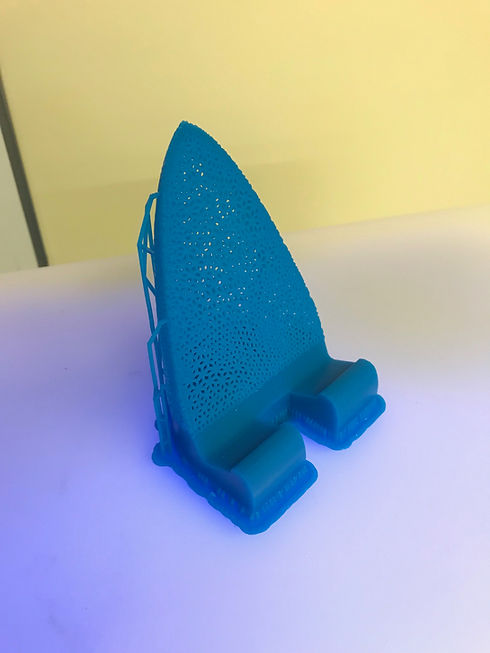

Latticed Phone Stand

September 2019 - October 2019

In this project, I investigated the latticing software nTopology and the ability to 3D print lattices using SLA technology. The project was an assignment for my graduate level additive manufacturing course. Over a number of iterations of this phone stand, I learned how to design for additive manufacturing using lattices by developing an understanding of how to make self-supporting structures. I also learned how to use nTopology and became further versed in using Formlabs' PreForm.

Prototyping

A draft printed in FDM to just model out the geometry intended and see if it worked. Include what was good and what needed to change and why, and next steps (ie apply8ing the lattice and printing in SLA)

Latticing in nTopology

|  |  |

|---|---|---|

|

Challenge was creating a lattice that would be printable in SLA on a Formlabs Form 2 Printer in draft resin. This required that all angles be at or below 45 degrees to the horizontal and that there are no 'unsupported minima' when the latticed model is placed in the slicer. The above iterations did not prove to be sufficient, since all of them were extremely large files that PreForm could barely support, and each had a large number of unsupported minima that could not be mended. The original CAD design of the phone stand needed to be changed to be at shallower angles to ensure that there would be less unsupported minima when a lattice was applied. Similarly, it was concluded that applying a lattice to the entire model was adding unnecessarily complicated geometry to the model, and therefore that the weight bearing portion supporting the phone could be solid.

Final Design & Print

|  |  |

|---|---|---|

|

The final design included a steeper angled top to ensure 45 degree angles and supported minima. The weight supporting portion of the piece was made solid. Once placed into the slicer, the design was printed in draft resin.