Shiv Denner

Project/Program Manager with Aerospace and Additive Manufacturing Industry Experience.

Engineering Portfolio

Over my four years studying mechanical engineering at Boston University, I've accumulated a number of engineering projects that I take pride in. Whether assigned through a class or done in my spare time, many of my projects incorporate creative elements. Recently, I've taken an interest in combining engineering with jewelry making.

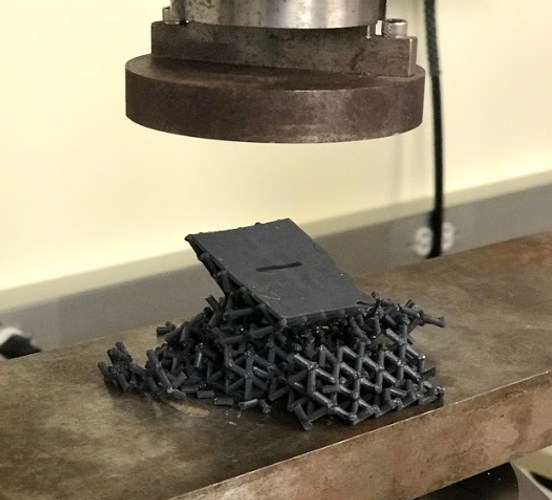

Properties of Lattice Structures Under Compression

My senior design group is tasked to create a latticed midsole for Vibram. Before we can 3D print and deliver the final midsole, the first step is to determine the type of lattice that best meets the needs of our client: the lattice that can hold the most weight without being completely destroyed. This experiment outlines our process of deciding the type of lattice to use in the midsole.

2.5 Axis Automated Plant Watering Machine

This team project called for the design and manufacture of a product that integrates programming, motor use, product design, machining, CAD drawing, and teamwork skills to create a 2.5 axis machine. The team created a plant watering system manually controlled by a joystick that could be moved in the x and y directions. A solenoid valve controlled the flow of water from the tank and tube and out of the watering can-style shower head.

Arduino "Snake" Controller

The purpose of this project was to create an interface that would allow a user to interact with a virtual environment. Effectively, by programming an ArduinoUNO to communicate with a Python code, users can provide real-life inputs that would cause a virtual output to be generated. Skills in both design and coding were employed during this project, as both the Arduino and Python interfaces were used to code, and 3D printing, machining, CAD designing, and the like were used to design the physical controller.

Latticed Phone Stand

Originally assigned as a project for a graduate level course on additive manufacture, this project challenged me to create any weight bearing item and simplify its design via lattice. By using NTop software and SLA 3D printing, a partner and I created a phone stand with a lattice to reduce weight and enhance aesthetics.

Hot Wire Tool

This project, which was completed with a group of 3 other students, was meant to introduce molding and casting processes to create components of prototypes. By creating an ergonomic hot-wire tool, the team was able to display the ability to create a functioning prototype using additive technologies as well as the previously mentioned molding and casting processes. The function of the end product was a foam-cutter in the shape of a hand gun, complete with finger forming indentations to maximize comfort during use.

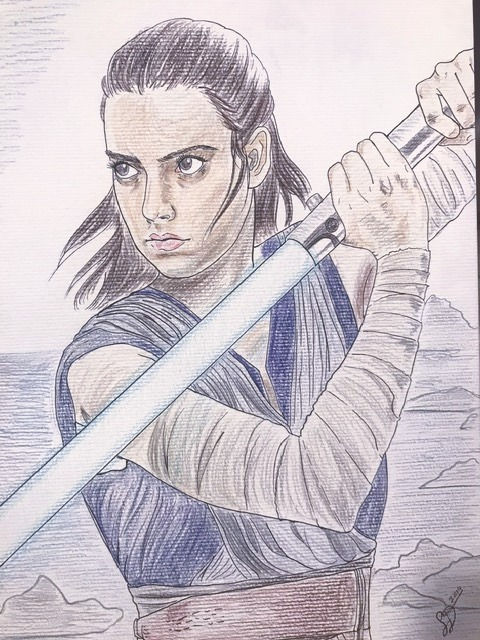

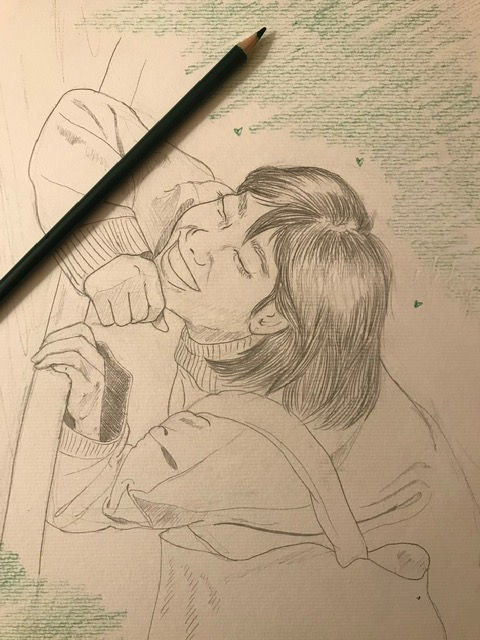

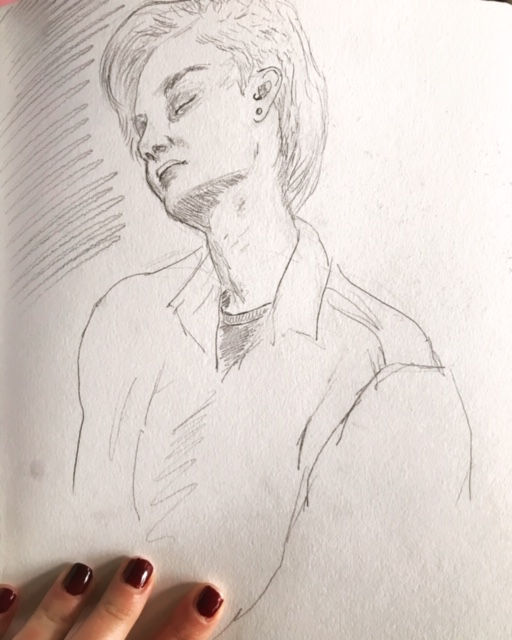

Art Portfolio

In my spare time I prefer to keep my hands busy, so I naturally took up illustrating and crafting as hobbies. I enjoy watercolor, portrait drawing, jewelry making, crocheting, macrame, cooking, and baking. Featured below are photos of some of my work.